Steel - Industries

A variety of steel products are used to manufacture automotive bodies and parts. In particular, steel with light weight and high rigidity is required to ensure passenger safety while improving fuel/energy efficiency. Depending on the characteristics of the part, workability, and corrosion resistance are also crucial. We supply high-quality automotive steel sheets, namely GIGA STEEL, to global automakers and parts companies, and we are pioneering new demands with specialized products in line with the growth of the eco-friendly automotive market.

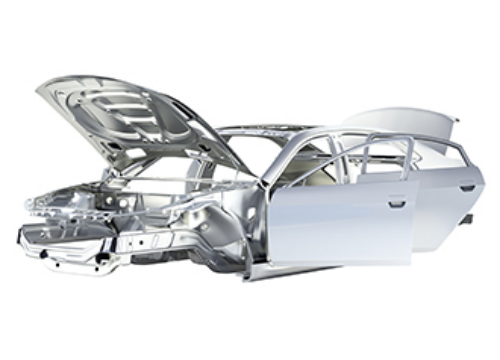

Body

The body plays a critical role in safeguarding passengers during vehicle accidents as it absorbs and disperses shocks. For electric vehicles (EVs), it also shields the battery from damage. Comprised of outer and inner panels, the body is subject to diverse performance requirements, including formability, paintability,image clarity, workability, weldability, and corrosion resistance, depending on the part.

Chassis

The chassis serves as the fundamental component governing a car's driving performance, encompassing suspension, steering, exhaust, and braking systems. Each part has unique requirements, such as fatigue durability properties, corrosion resistance, workability, and weldability, depending on its specific function.

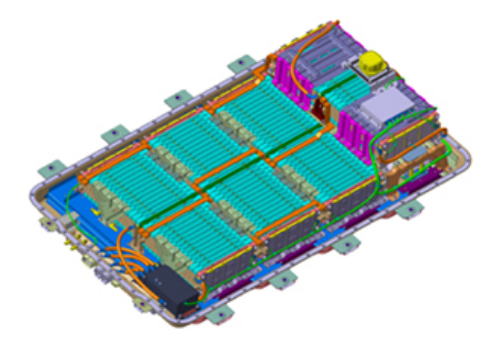

EV Battery Pack

A battery stores electrical energy as chemical energy and later converts it to electricity as needed. It typically comprises a cell, module, and case. The components made of stainless steel and cold rolled steel provide protection against external factors, including shock, heat, and vibration.

EV Traction Motor

The drive motor is equivalent to the engine of internal combustion engine (ICE) vehicles. It uses the power of the current to turn the drive shaft. To enhance efficiency, it requires electrical steel with minimal power loss, and our electric steel, Hyper NO, offers a viable solution.

Related Products

For Hydrogen Fuel Cell

Comprising a stack of proton-exchange membranes (PEMs) and separators, it serves as the engine of hydrogen vehicles by generating electrical energy from hydrogen. The separators serve as a channel through which hydrogen and air pass, and they are made of stainless steel for corrosion resistance in harsh conditions.

Related Products

Recently, the importance of ESG factors such as carbon and fine dust reduction and safety improvement is rising in the construction industry. Steel is a future construction material that is recyclable and has a longer service life compared to conventional construction materials such as stone, wood, and concrete. Through our brand Innovilt, we offer construction steel materials for structural, interior, and exterior use while focusing on reinforcing the domestic and international steel ecosystem based on partnerships with major manufacturers of steel pipes and steel balls.

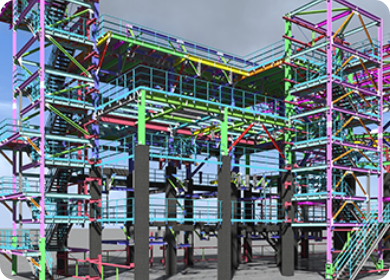

Architectural Structures

Various types of structural systems are applied to construct taller and safer buildings. In addition, the main structures of a building are incorporated with H-shaped steel and steel pipes by using steel materials that are robust and earthquake-resistant in order to make these structure systems much more efficient. Additionally, buildings are incorporated with the seismic design, ensuring they possess deformation capacity for plastic deformation, reproducibility of collapse mechanisms, and weldability. Our steel for architectural structures meets seismic design regulations, featuring a yield point and yield ratio that comply with the regulations, and is supplied as heavy steel plates and hot rolled plates.

Related Products

Interior and Exterior

Architectural interior and exterior steel serves as the primary finishing material as it defines a building's appearance and functionality. Produced in various patterns and colors, it enhances aesthetics and ensures a comfortable and safe building environment by providing insulation and fire resistance. Weather-resistance steel, PosMAC, and stainless steel are applied, and they boast superior corrosion resistance compared to standard steel, ensuring durability in atmospheric conditions.

POSCO is leading the shipbuilding industry as the major supplier of quality steel to shipbuilders worldwide, including the global Big 3.

Steel used for shipbuilding requires special properties that allow ships to withstand the load from their hulls and cargo therein as well as other external forces that the ships might experience during their voyage. Our products intended for this industry are typically used for regular ships, and special naval vessels. With recent technological advancements and more trade volume, ships have become larger and larger. Meanwhile, naval vessels require weight reduction and greater performance.

Steel used for shipbuilding requires special properties that allow ships to withstand the load from their hulls and cargo therein as well as other external forces that the ships might experience during their voyage. Our products intended for this industry are typically used for regular ships, and special naval vessels. With recent technological advancements and more trade volume, ships have become larger and larger. Meanwhile, naval vessels require weight reduction and greater performance.

Regular Ship

In general, there are various types of ships, including oil tankers, bulk carriers, container ships, and LNG carriers. As technology advances and cargo volumes increase, ships are becoming larger and must operate safely in harsh marine environments, such as rough waves and strong winds. Therefore, they must meet strict requirements such as high strength, CTOD (Crack Tip Opening Displacement) and BCA (Brittle Crack Arrest). POSCO supplies the world’s top premium steel for shipbuilding, including steel plates for low-temperature pressure vessels, 9% Ni steel, high manganese steel, and steel plates for LNG tankers.

For Special Naval Vessel

Navy vessels must be bulletproof or withstand high pressure like submarines, and demand lighter and faster performance. In addition to steel plates for shipbuilding and high-strength steel certified by classification societies, special steels such as defense-grade steel are also applied.

Related Products

With the rapid growth of the eco-friendly renewable energy industry, the importance of steel as a core material is once again gaining recognition. As a total solution provider, we are fulfilling our role by proactively responding to the demand for steel materials by the eco-friendly energy industry, such as solar power, wind power, hydrogen, and CCUS.

Solar Generation

Solar Generation

Solar power is the conversion of energy from sunlight into electricity (direct current, or unidirectional flow of electric charge).

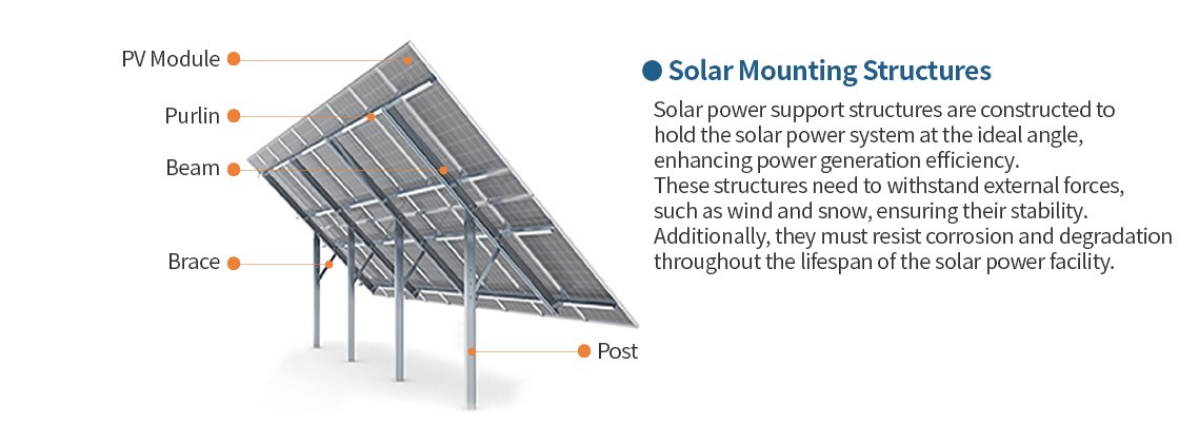

Solar Mounting Structures

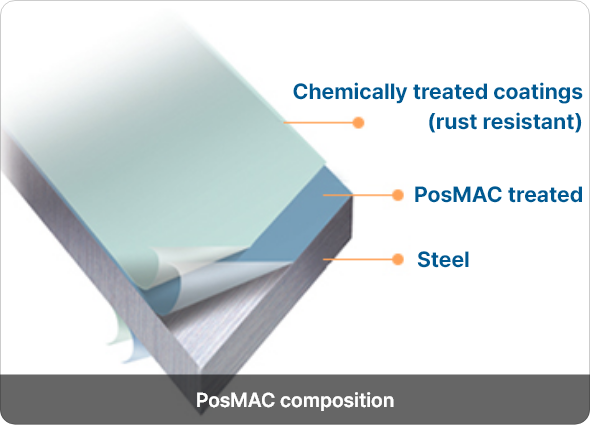

Anti-corrosive PosMAC (POSCO Magnesium Aluminum Alloy Coating)

Solar panels must be supported by a structure that can prevent them from breaking or being disassembled. For their maintenance, solar panels require foundations beneath them through which people can gain access. Many of these foundations are made of PosMAC, which is highly resistant to corrosion while also being highly durable.

In general, steel has a durability issue because of its vulnerability to corrosion. PosMAC features the highest corrosion resistance of all galvanized steels in the world. As it has a coating layer, which consists of three elements, magnesium, zinc, and aluminum, it delivers 5 to 10 times higher corrosion resistance than regular galvanized steel plates. This allows solar power generators to use the material for a long time without any worries about corrosion.

In general, steel has a durability issue because of its vulnerability to corrosion. PosMAC features the highest corrosion resistance of all galvanized steels in the world. As it has a coating layer, which consists of three elements, magnesium, zinc, and aluminum, it delivers 5 to 10 times higher corrosion resistance than regular galvanized steel plates. This allows solar power generators to use the material for a long time without any worries about corrosion.

Related Products

Wind Power Generator

Wind Power Generator

Wind power generation refers to the use of the wind to turn the generator (wind turbine) and generate power. Many countries regard wind power as a clean and relatively cheap energy source, and it has been widely adopted all across the globe. Recently, there has been an expansion in wind turbine installations into offshore areas where the wind blows strongly.

Tower & Substructure

The majority of wind turbine towers and foundations are constructed with heavy steel plates. Specifically, heavy steel plates adhering to the EN10025 standard are frequently selected for wind power infrastructure.

Generator Core

The turbine motor is a component that transforms the rotational force generated by wind acting on the blades into electricity. POSCO's high-quality NO is utilized for this part. POSCO's Hyper NO exhibits consistent magnetic properties regardless of its orientation, making it especially suited for rotational applications. This material not only enhances energy efficiency by minimizing power losses in motors but also sustains stable power output even when the motor's size is downsized.

Bearing

Bearings, integral to the rotating parts of a wind turbine, are primarily crafted from "extreme blue bearing steel." These products, made of steel bars and wire rods, have their attributes and standards managed in compliance with DIN50602.

Bolt & Nut

Hex bolts, which secure the wind turbine to the tower, as well as the bolts that fasten the blade to the nacelle, are manufactured by using steel bars and wire rods. Their quality and properties adhere to the DIN50602 standards.

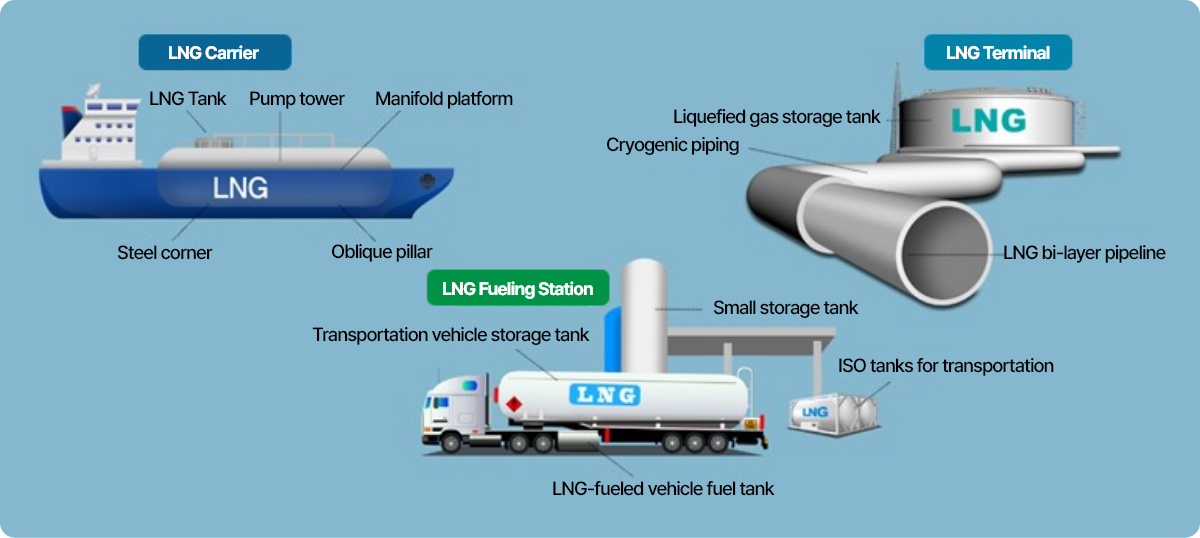

LNG Carrier

LNG Carrier

This vessel carries the methane (CH4, the primary element of LNG) used in homes and factories in a liquefied state.

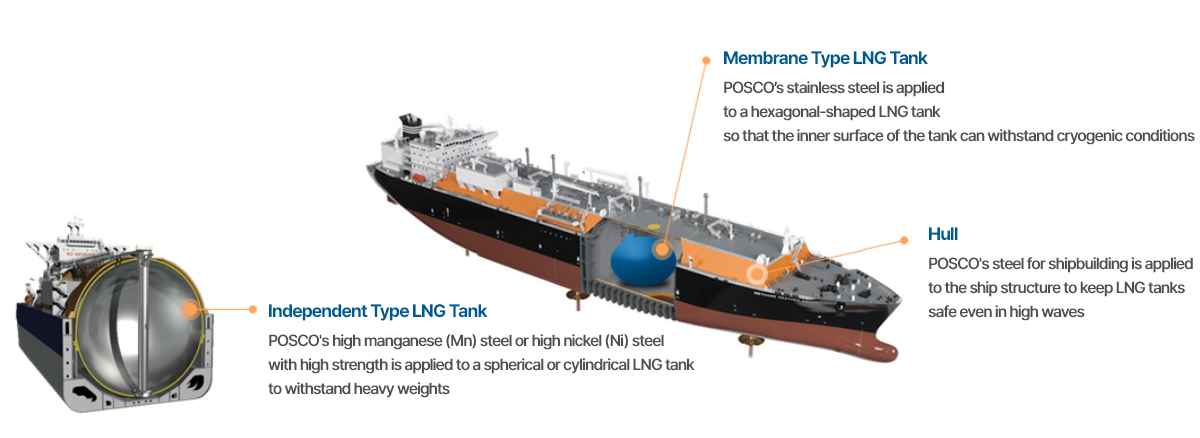

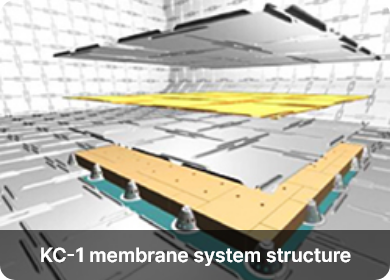

Membrane Type LNG Tank

Stainless steel for LNG tanks that can withstand temperatures of -163 °C

The tank, which is often of a hexagonal membrane type, stores liquefied natural gas (LNG). Such a type and shape allow the tank to store a large amount of gas efficiently without loss of space. LNG experiences a dramatic change in its temperature while it is transported from offshore to onshore.

Its temperature is extremely low (-163 °C) during transportation, but rises all the way up to 20-30 °C afterward. In general, steel is highly apt to break upon impact at very low temperatures or in the event of a dramatic change in the temperature. We use stainless steel for membrane-type LNG tanks to prevent breakage upon impact or in the event of a dramatic change in the temperature.

Its temperature is extremely low (-163 °C) during transportation, but rises all the way up to 20-30 °C afterward. In general, steel is highly apt to break upon impact at very low temperatures or in the event of a dramatic change in the temperature. We use stainless steel for membrane-type LNG tanks to prevent breakage upon impact or in the event of a dramatic change in the temperature.

KC-1 source: Korea Gas Corporation

Related Products

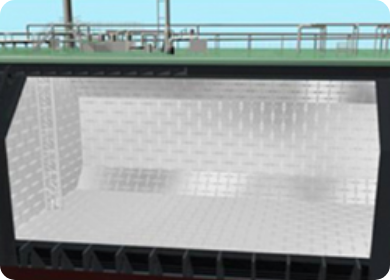

Independent LNG Tank

High manganese steel that does not break at as low as -196 °C

Independent LNG tanks are of spherical or cylindrical shape, and they must be able to withstand heavy weight. For this application, our high manganese steel or high nickel steel is used.

High manganese steel is a new steel type made by adding 3 to 27 percent of manganese to steel. Even in extreme low-temperature environments of -196 °C, it does not break, and because it is more economical than the expensive steel materials previously used, it can reduce the cost of steel and welding materials. Ultra-low temperature high manganese steel is widely used for storage containers for liquefied gas, such as ships or onshore LNG storage tanks.

High manganese steel is a new steel type made by adding 3 to 27 percent of manganese to steel. Even in extreme low-temperature environments of -196 °C, it does not break, and because it is more economical than the expensive steel materials previously used, it can reduce the cost of steel and welding materials. Ultra-low temperature high manganese steel is widely used for storage containers for liquefied gas, such as ships or onshore LNG storage tanks.